'hemp house' by werner aisslinger

like his 'hemp chair,' this structure is made of more than 70% natural fibers such as hemp and kenaf,

bound together with acrodur, a water-based acrylic resin from german chemical company BASF.

the curing procedure thus releases no harmful substances and water is its only byproduct.this compression of renewable raw materials forms a new environmentally-friendly composite that is lightweight yet durable.

says aisslinger, 'design history is driven by new technologies and material innovation.

for us designers, the advent of these technologies has always been the starting point for new objects and typologies in design.'

for more information on 'hemp chair,' please see designboom's previous article about the project.

image by michel bonvin, courtesy of studio aisslinger

'hemp house' at DMY berlin 2011

image © designboom

image © designboom

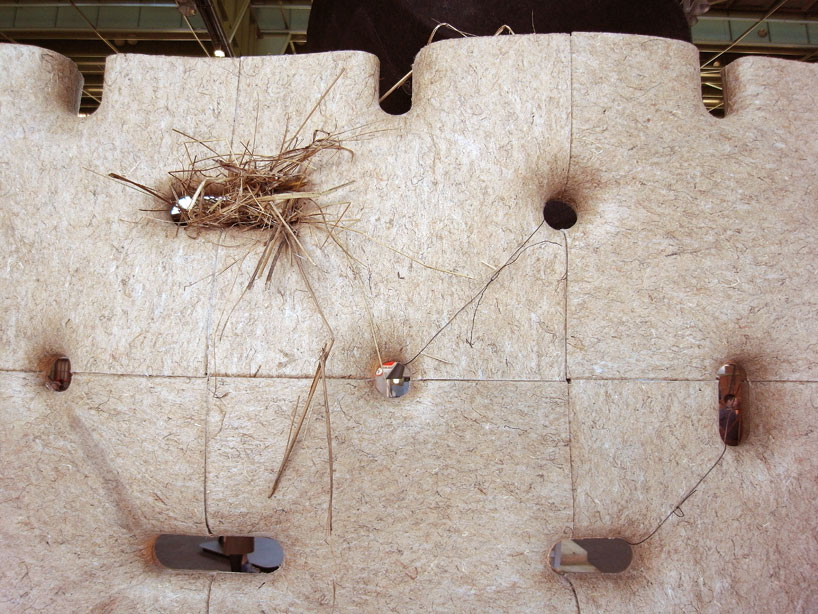

wall and ceiling detail

image © designboom

image © designboom

image © designboom

'hemp chair' at DMY

image © designboom

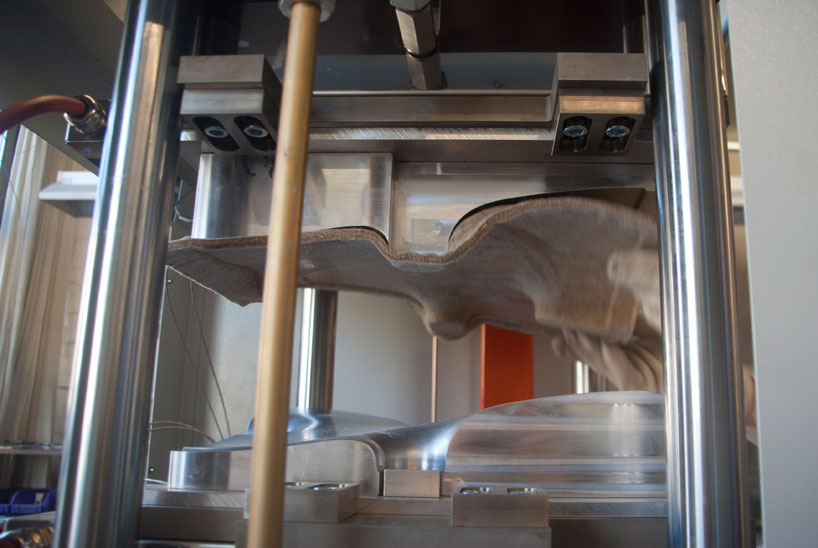

the method of manufacturing 'hemp house' panels draws from the automobile industry,

in which compression molding of natural fiber composites is common for parts such as door linings, glove compartments and rear shelves.

this industrial process enables low-cost mass production of lightweight material with a high mechanical resistance.

compression molding of a panel

image by michel bonvin, courtesy of studio aisslinger

stacks of panels after production

image by michel bonvin, courtesy of studio aisslinger

cross-linking process

image by michel bonvin, courtesy of studio aisslinger

sheets of connected panels create a surface

image by michel bonvin, courtesy of studio aisslinger